Cosmetics

Ensuring process reliability in cleaning production containers, mixing vessels, and reactors is crucial for success in manufacturing substances and products in the cosmetics industry. Cleanliness is paramount for achieving high quality. Our automated cleaning systems are efficient, saving both time and resources, and they are also cost-effective. Leveraging high-pressure technology provides numerous benefits and ensures sustainable production practices.

Application areas

-

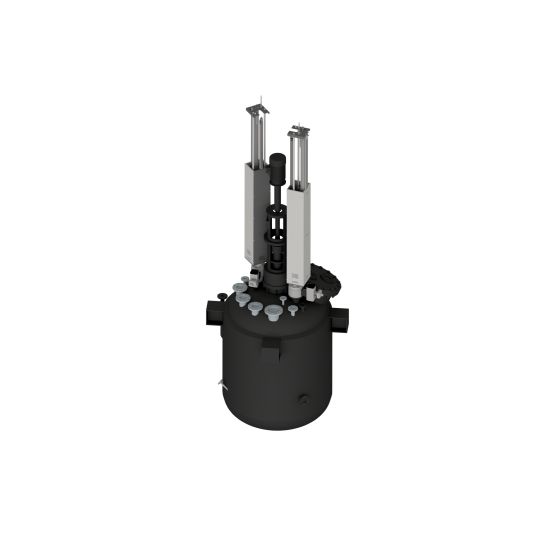

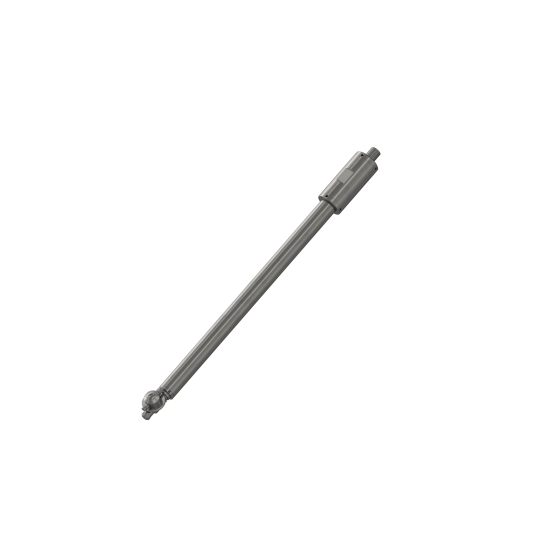

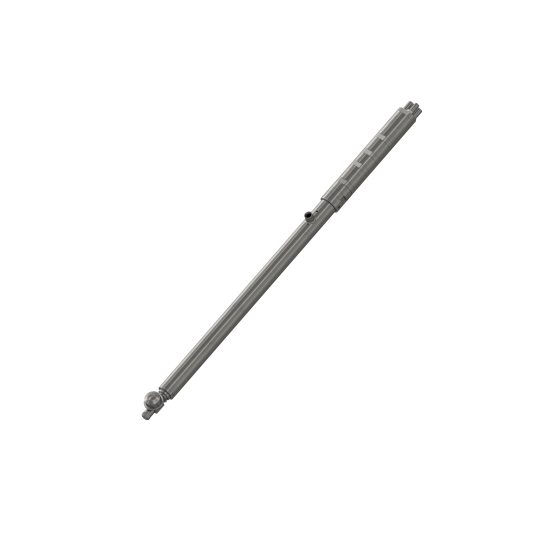

Production vessels, continuous stirred-tanks and reactors

Automated high-pressure cleaning for a wide range of viscous products and substances.

-

Production areas

The stationary high-pressure cleaning systems enable fast and thorough cleaning of equipment and floors and offer a variety of additional options.

-

Transport container

The semi-automatic high-pressure cleaning is powerful and flexible to use.

User benefits

-

Efficiency

High-pressure cleaning with cold/hot water, without the addition of chemicals. Optimum pressure and metered jet guidance achieve constant and process-reliable results.*

High-pressure cleaning with cold/hot water, without the addition of chemicals. Optimum pressure and metered jet guidance achieve constant and process-reliable results.*

-

Conservation of resources

Sustainability thanks to high water and energy savings, no or minimal use of chemicals.

Sustainability thanks to high water and energy savings, no or minimal use of chemicals.

-

Reliability

High-quality materials, robust design, precision manufacturing, operational reliability (guaranteed service and support) and easy maintenance.

High-quality materials, robust design, precision manufacturing, operational reliability (guaranteed service and support) and easy maintenance.

-

No additional infrastructure effort

Despite high performance, no additional power supply at the tank due to optional water-hydraulic drive of the cleaning heads.

Despite high performance, no additional power supply at the tank due to optional water-hydraulic drive of the cleaning heads.

-

Economic efficiency

Savings in cleaning time, personnel costs, reduction in water consumption and other resources, long service life (value retention).

Savings in cleaning time, personnel costs, reduction in water consumption and other resources, long service life (value retention).

-

ATEX conformity

Through optional compressed air drive or water hydraulic drive in ATEX environment1) .

1) ATEX (ATmosphères EXplosibles) is the short description for the strict EU directives on explosion protection.

Through optional compressed air drive or water hydraulic drive in ATEX environment1) .

1) ATEX (ATmosphères EXplosibles) is the short description for the strict EU directives on explosion protection.