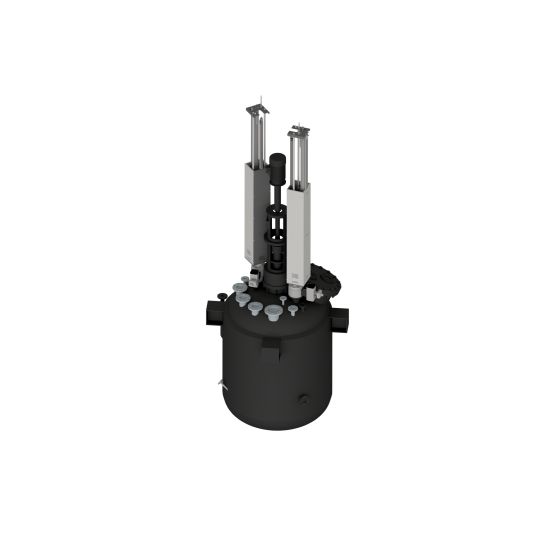

Paint and varnish

The paint and varnish industry sets the highest standards for flawless quality and speed of cleaning results in production. The MOOG Cleaning Systems clean containers and tanks of different dimensions as simply as efficiently - distinctly user-oriented in every detail, perfect in the result and ATEX-compliant.

Application areas

-

Storage tanks and production containers

Automatic interior cleaning for a wide range of dimensions.

-

Production areas

Fast and thorough high-pressure cleaning of equipment and floors with automatic dosing of cleaning agents.

-

Transport containers

Automatic interior cleaning for chemical transport containers and with additional manual exterior cleaning.

User benefits

-

Efficiency

High-pressure cleaning with cold/hot water. Reproducible results thanks to programmed jet guidance.

High-pressure cleaning with cold/hot water. Reproducible results thanks to programmed jet guidance.

-

Conservation of resources

Sustainability thanks to high water and energy savings, no or minimal use of chemicals.

Sustainability thanks to high water and energy savings, no or minimal use of chemicals.

-

Reliability

High-quality materials, robust design, precise manufacturing, operational reliability (guaranteed service and support) and easy maintenance.

High-quality materials, robust design, precise manufacturing, operational reliability (guaranteed service and support) and easy maintenance.

-

No additional infrastructure effort

Despite high performance, no additional power supply at the tank due to optional water-hydraulic drive of the cleaning heads.

Despite high performance, no additional power supply at the tank due to optional water-hydraulic drive of the cleaning heads.

-

Economic efficiency

Savings in cleaning time, personnel costs, reduction in water consumption and other resources, long service life (value retention).

Savings in cleaning time, personnel costs, reduction in water consumption and other resources, long service life (value retention).

-

ATEX conformity

Certified for use in ATEX1) environments by optional compressed air drive or water hydraulic drive.

1) ATEX (ATmosphères EXplosibles) is the short description for the strict EU directives on explosion protection.

Certified for use in ATEX1) environments by optional compressed air drive or water hydraulic drive.

1) ATEX (ATmosphères EXplosibles) is the short description for the strict EU directives on explosion protection.